Thermal Imaging of Your Electrical Systems

Your electrical system that powers your facility cannot afford to have an unexpected failure or shut down. An Infrared Inspection of all electrical components can save you down-time by finding the problems before they find you. At Thermal Techniques, our Certified Thermographers have the training, experience, and knowledge that’s necessary to ensure that a catastrophic failure does not occur.

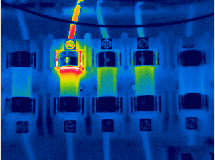

Now let’s look at a simple find or example through the power of Thermal Imaging;

In the picture below, visually everything appears to be quite normal, clean and in good condition. However, Thermal image of the same fuses reveals the electrical components are actually at high risk of failure with Temperatures in excess of 200°F.

At Thermal Techniques we refer to this as an opportunity for improvement for our customer. This sort of finding can save you unexpected losses in downtime of production, which can quickly add up to high monetary losses. Our certified Infrared Thermographers will point out these types of issues immediately during the inspection. These findings will also be thoroughly explain in a detailed report sent soon after the inspection has been performed. Our infrared inspection service of your facility will allow you to find tomorrow’s problems today.

Every year in the United States, faulty electrical/lighting equipment causes more than 45,000 structural fires. On average, these fires kill 240 people, injure 1,200, and inflict more than $1 billion in direct property damage. (NFPA)

Advantages of Thermal Imaging for Electrical Components

- Increases safety

- Fire prevention

- Reduces production Down-Time

- Prevents premature failure of Equipment

- Identifies potentially dangerous faulty equipment

- Quickly locates problems, without interrupting service

- Help reduce insurance costs

What Electrical Infrared Scans Reveal

Infrared Thermal Imaging can be an invaluable resource in the assessment of your electrical systems. Consider what the technology may uncover for you:

- Pinpoint accuracy of the electrical equipment’s failing or compromised components.

- Faults in power distribution systems that can be related to increases in resistance or current, load imbalance, and harmonic currents.

- Loose/Faulty cable connections, failing circuit breakers, degradation of insulation, corrosion, bad contacts in breakers and disconnects, as well as electrical structure failures.

- Transformer oil levels — easily detected.